sponsored

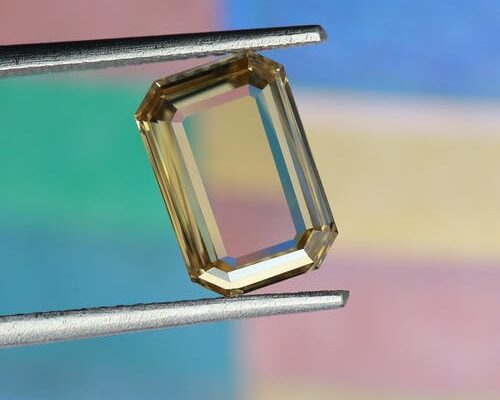

Diamond suspensions are products that are used during the preparation of samples to ease stock removal. They ensure that the surface is polished and 100% ready for analysis. The most efficient and effective diamond suspensions are known as 2-in-1 diamond suspensions. 2-in-1 diamond suspensions are an expertly blended mixture of premium diamond suspension and lubricant for superior performance.

In this article, we will be looking at some of the benefits of 2-in-1 diamond suspensions.

Save Time

For the best results, you must ensure that you have the right ratio of suspension and lubricant. This makes the process of dosing separate double suspensions and lubricants more complicated since you will have to do it all manually. On the other hand, using a 2-in-1 double suspension will save you lots of time because the two materials have been carefully blended for optimum preparation results. You will also be dosing just one material instead of two.

High Material Removal

Another great thing about 2-in-1 diamond suspensions is that they offer a much higher material removal rate than ordinary diamond suspensions. This doesn’t only guarantee the best results, but it also ensures that you use much less diamond suspension. This is because you will be able to achieve the necessary result while using lesser material.

Best Results

Finally, you can be assured of getting the best surface quality when you use a 2-in-1 diamond suspension. The material provides a consistent surface finish and particle size distribution. You will then be able to proceed with your task without fuss.

Conclusion

Akasel is a fast-growing company that provides optimized preparation methods for metallography. The company has different products for different kinds of materials, and you should visit the website today to find something that suits your needs. You will also get information on the most suitable suspension for every step.